Context: My major- Manufacturing and Design Engineering (MaDE) - has a year-long capstone consisting of finding a white space, using the design process to create a prototype, and creating a final product designed for manufacturing (DFM).

Problem Statement: How might we prevent plant death by alerting new plant owners when to water their plant without excluding the owners from the plant-care process?

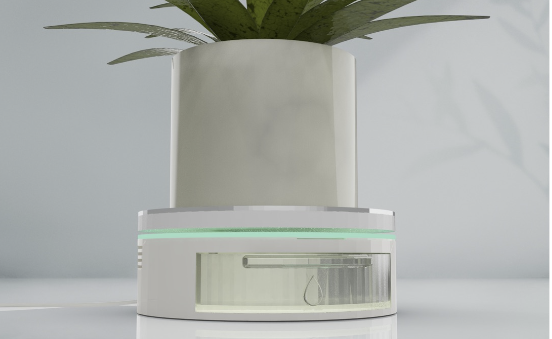

Outcome: My team created Florasense: a device that notifies new plant owners when to water their plant through a weight-based lysimeter. I diagnosed a quality issue through experimental design and data analysis, and I took charge of ideating and creating electronic prototypes.

Skills: Experimental Design, Data Analysis, Electronic Prototyping, Coding (C++), 3D Printing, Design for Manufacturing

White Space User Research

Our team discovered that many college students purchase plants for their ability to brighten up their room and for the experience of growing a living organism, but many students become discouraged when their plant dies despite their best efforts. To better understand the issue, we created a user profile- Jeremy- based on our research and interviews and created a journey map that showed the steps that led to plant death.

Through our user profile, journey mapping, and interviews, our team identified the reasons why new plant owners often kill their plants: overwatering, underwatering, not knowing when their plants need water, and ignoring the needs of their plant.

PROBLEM STATEMENT:

Owning and interacting with plants is beneficial for mental health and overall wellbeing. However, inexperienced owners often kill their plants due to forgetfulness or a lack of understanding of the plants and their needs. The death of the plants can have a negative effect on the owner.

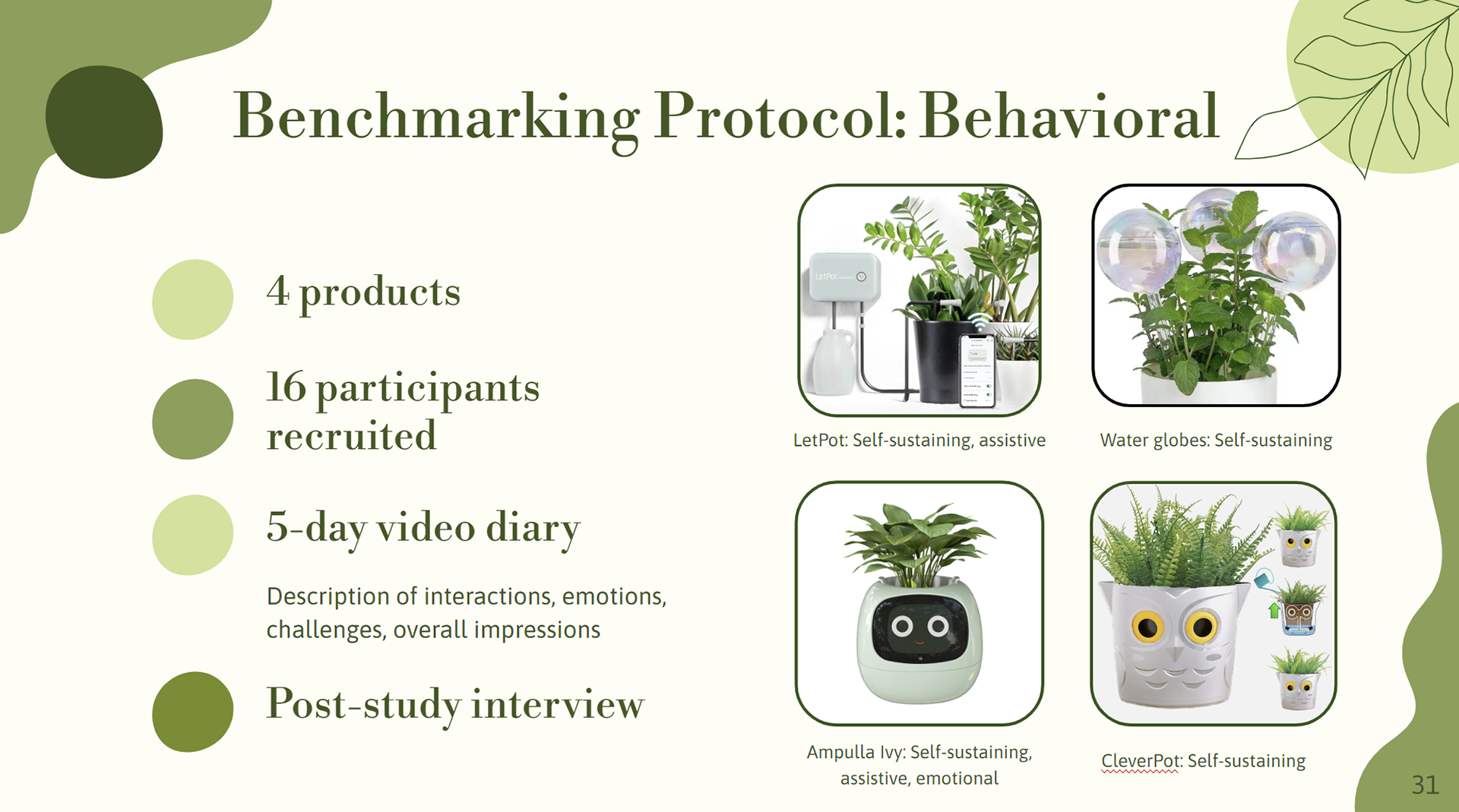

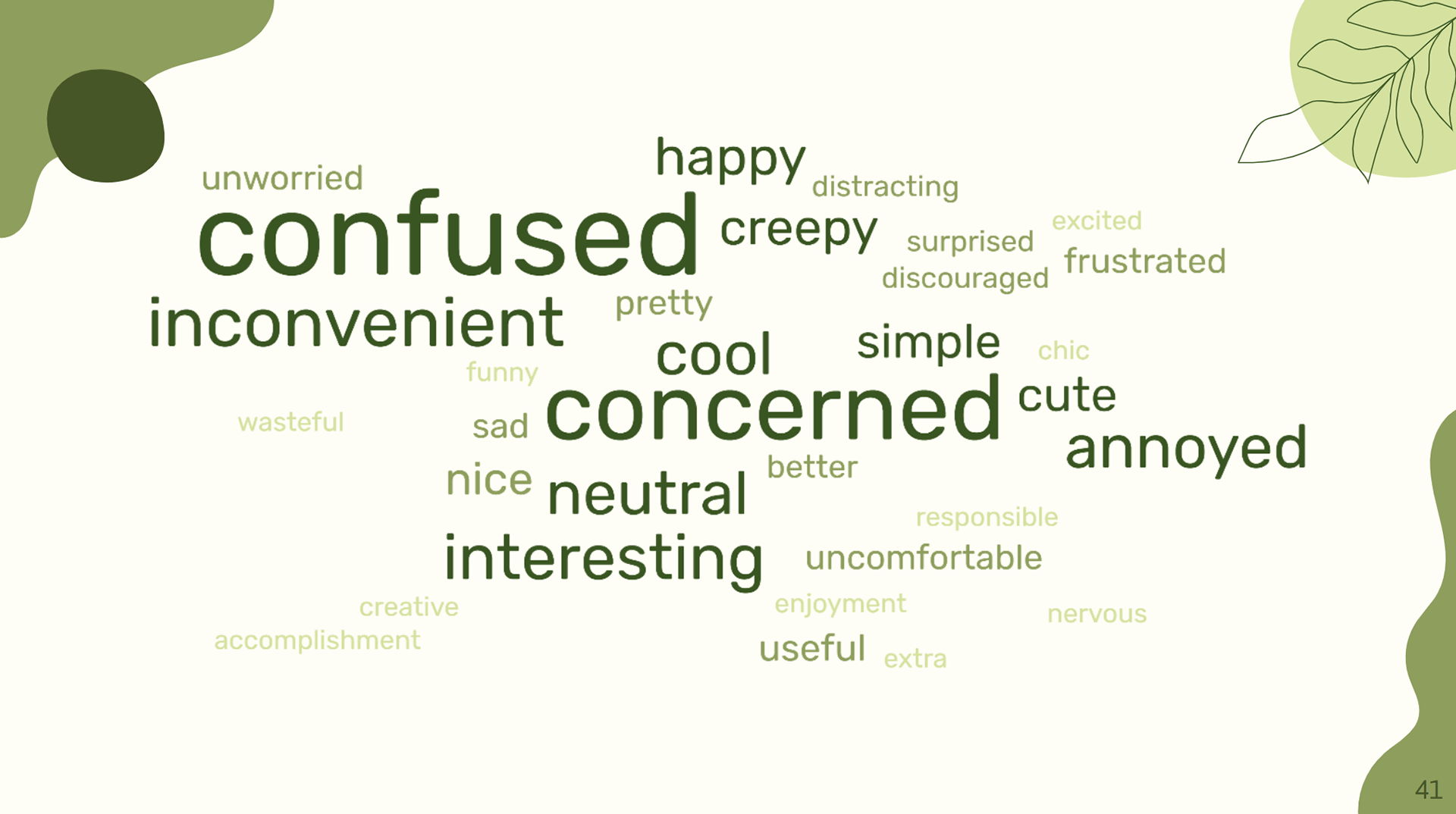

We tested several existing products on the market by recruiting sample users to grow plants using these products. Our users found the existing products to be creepy, inconvenient, and confusing.

Our product testing showed us that our product would have to teach the users how to actively care for their plant and encourage users to interact with their plant, rather than doing all of the work itself.

Foray One: Computer Vision

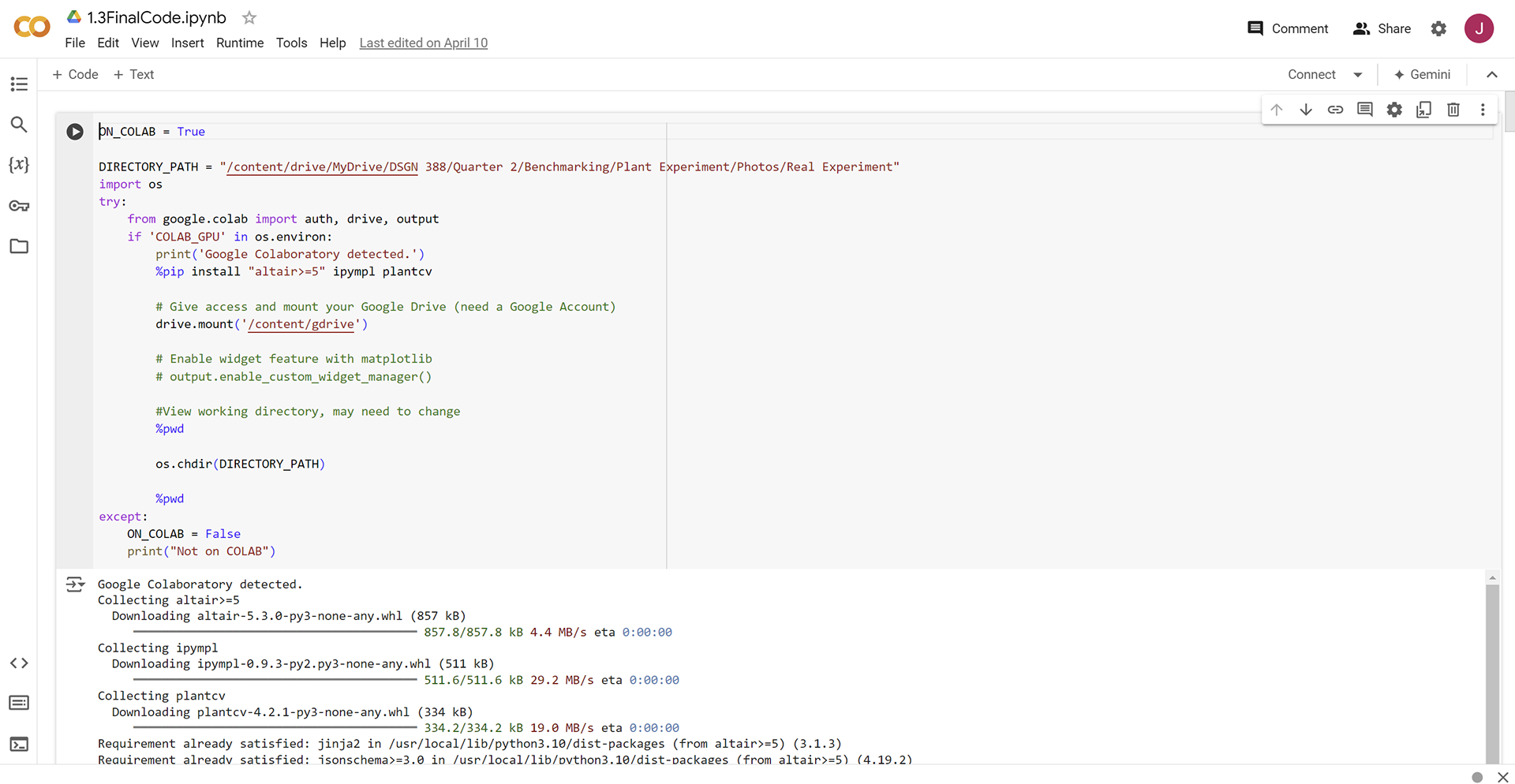

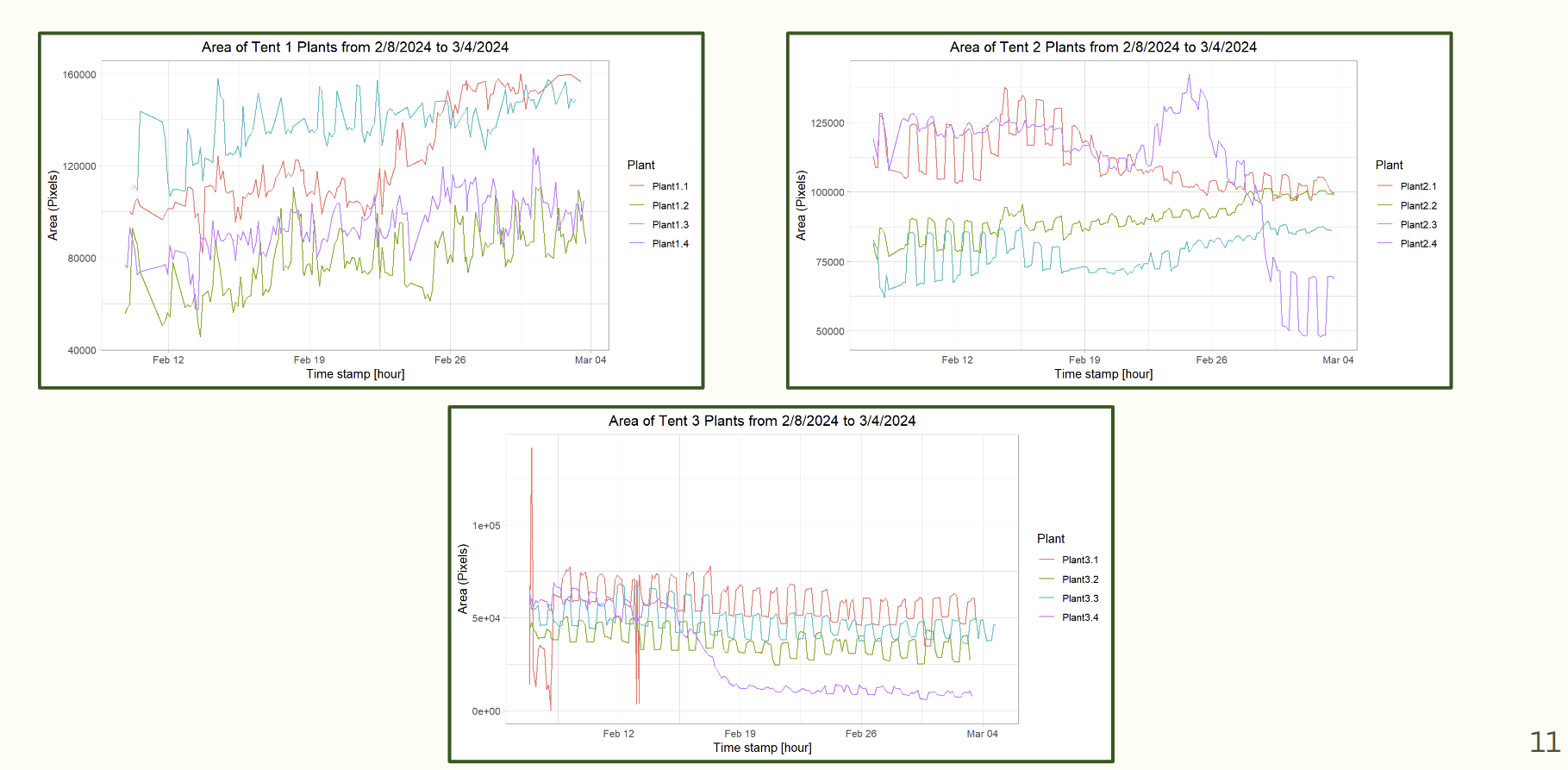

In order to quantify plant growth, we used a computer vision codebase I found called PlantCV. I set up timelapse cameras in front of test plants and recorded the growth of plants over a period of a month. Using the PlantCV codebase, we plotted the size of plants over time to see if we could match plant size with the correct time to water.

However, expert interviews and further research showed us that plants' phenotype are not the same across different species, meaning that we couldn't use computer vision to detect when a plant needs water.

Foray 2: Moisture Sensors

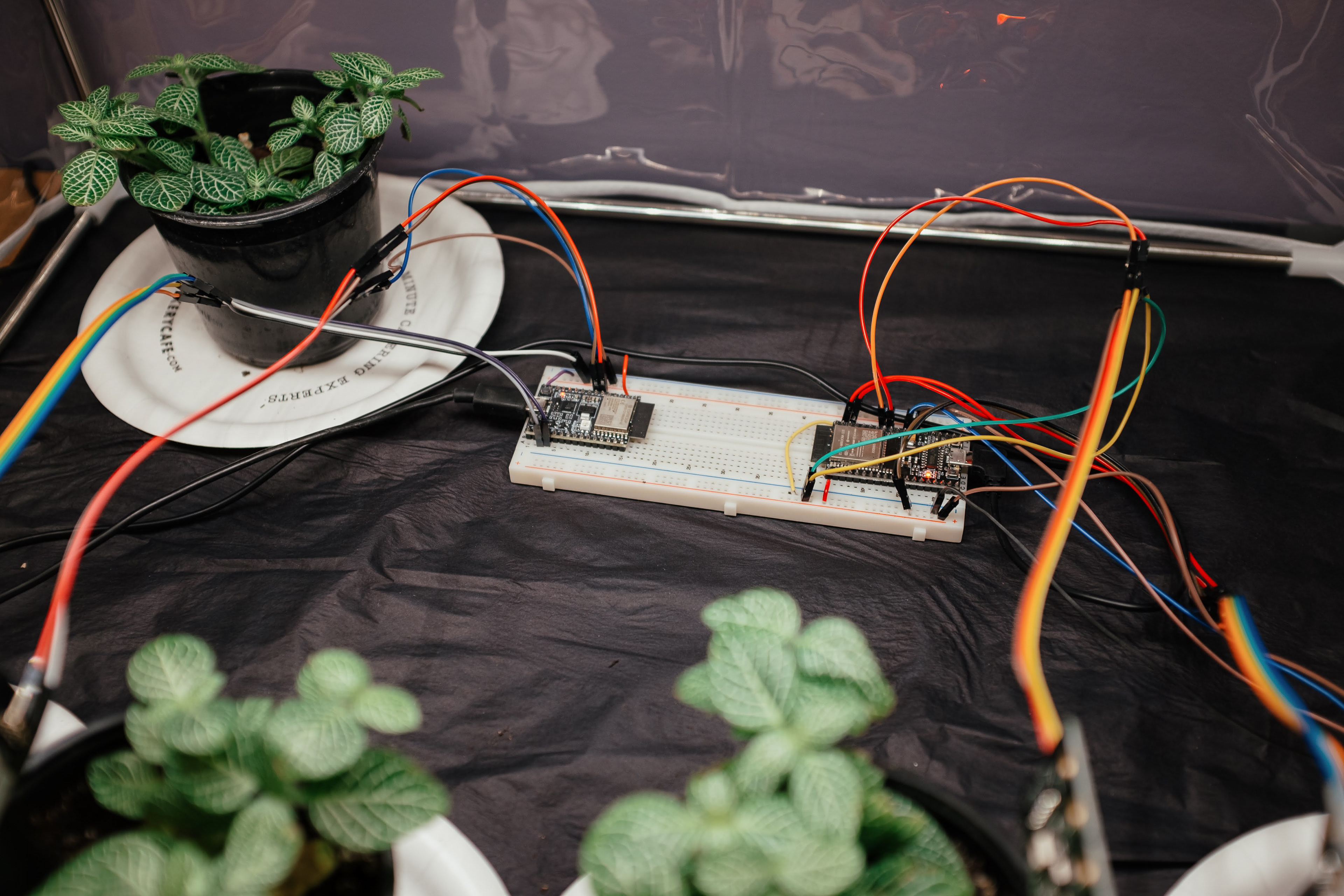

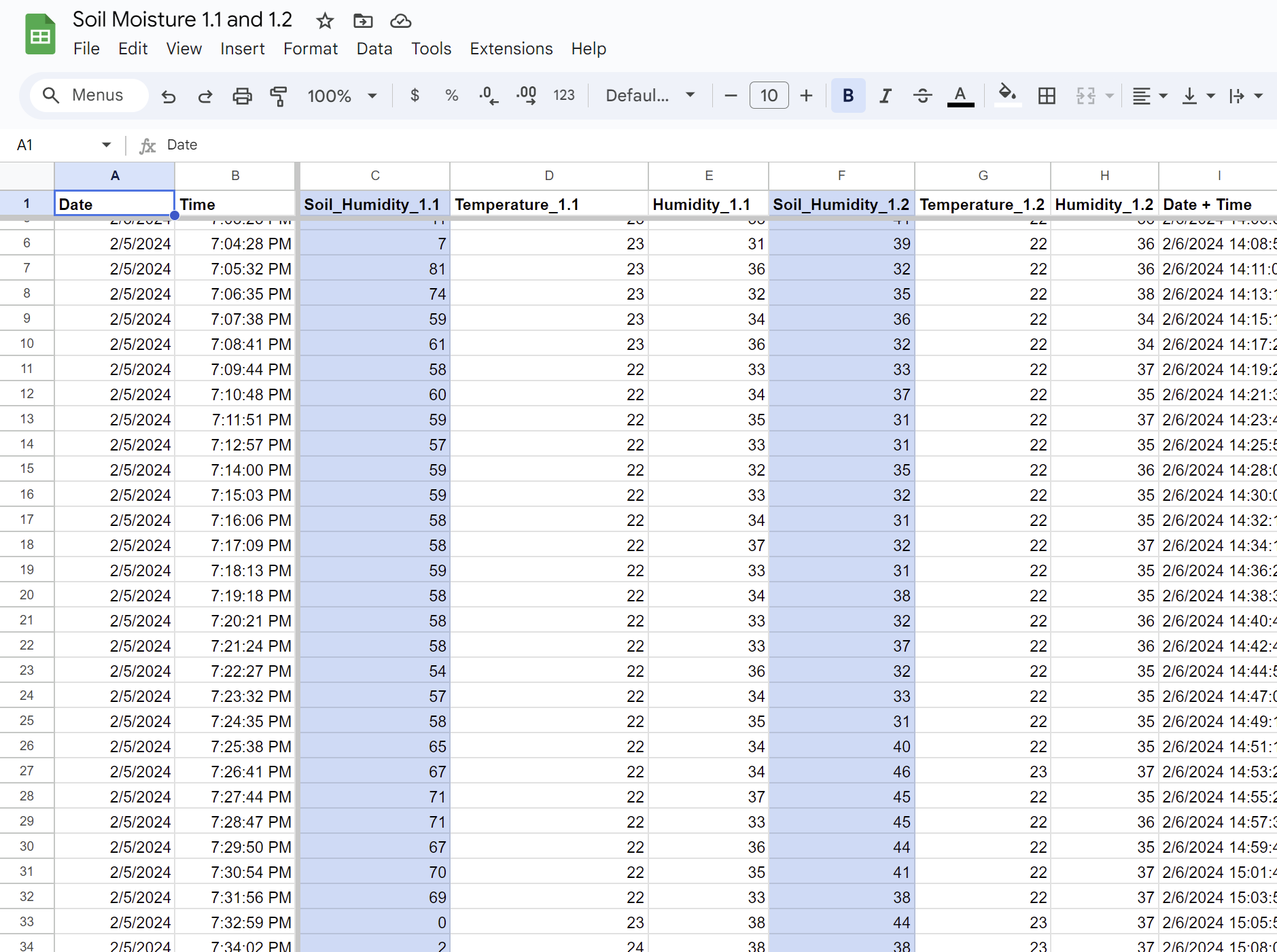

Our team looked at moisture sensors to detect when the soil was too dry and in need of water. I created a test setup of 12 plants and 12 moisture sensors transmitting via UART to ESP32s.

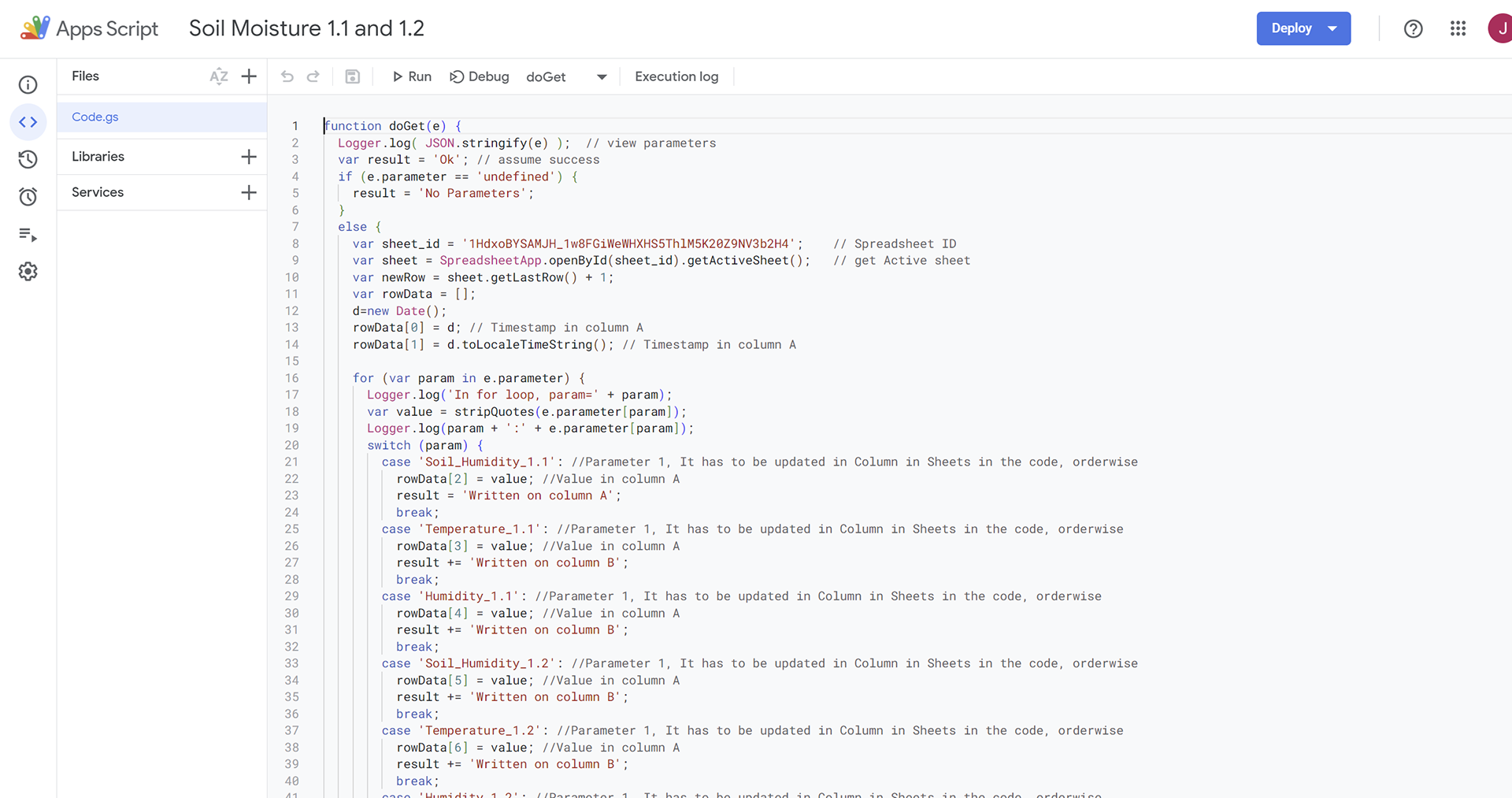

Using a Google Apps Script, I set up the ESP32s to transmit the soil moisture sensor readings into a Google Sheets for all 12 sensors over a period of a month.

However, we soon found several issues. The readings from our sensors were not consistent, with some staying at 100% moisture over several weeks. We found that soil moisture sensors were problematic in research, even with expensive sensors, and that there was no established soil moisture percentage at which plants should be irrigated.

Foray 3: Weight-Based Lysimeters (It's the last one!)

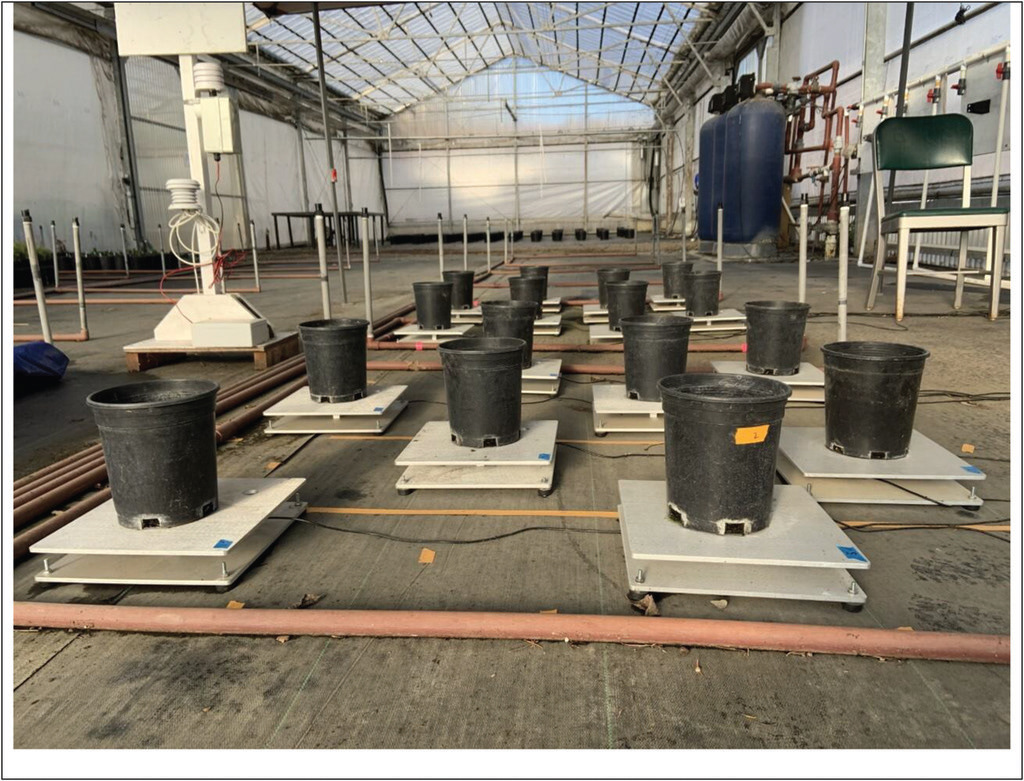

After our two failed forays into technologies, we looked at what researchers use to decide when to irrigate plants: weight. We came across the field of research in weight-based lysimeters; lysimeters are scales that constantly measure the weight of a plant.

(McCauley, D., Levin, A., & Nackley, L. (2021). Reviewing Mini-lysimeter Controlled Irrigation in Container Crop Systems. HortTechnology, 31(6), 634-641. Retrieved Jul 22, 2024, from https://doi.org/10.21273/HORTTECH04826-21)

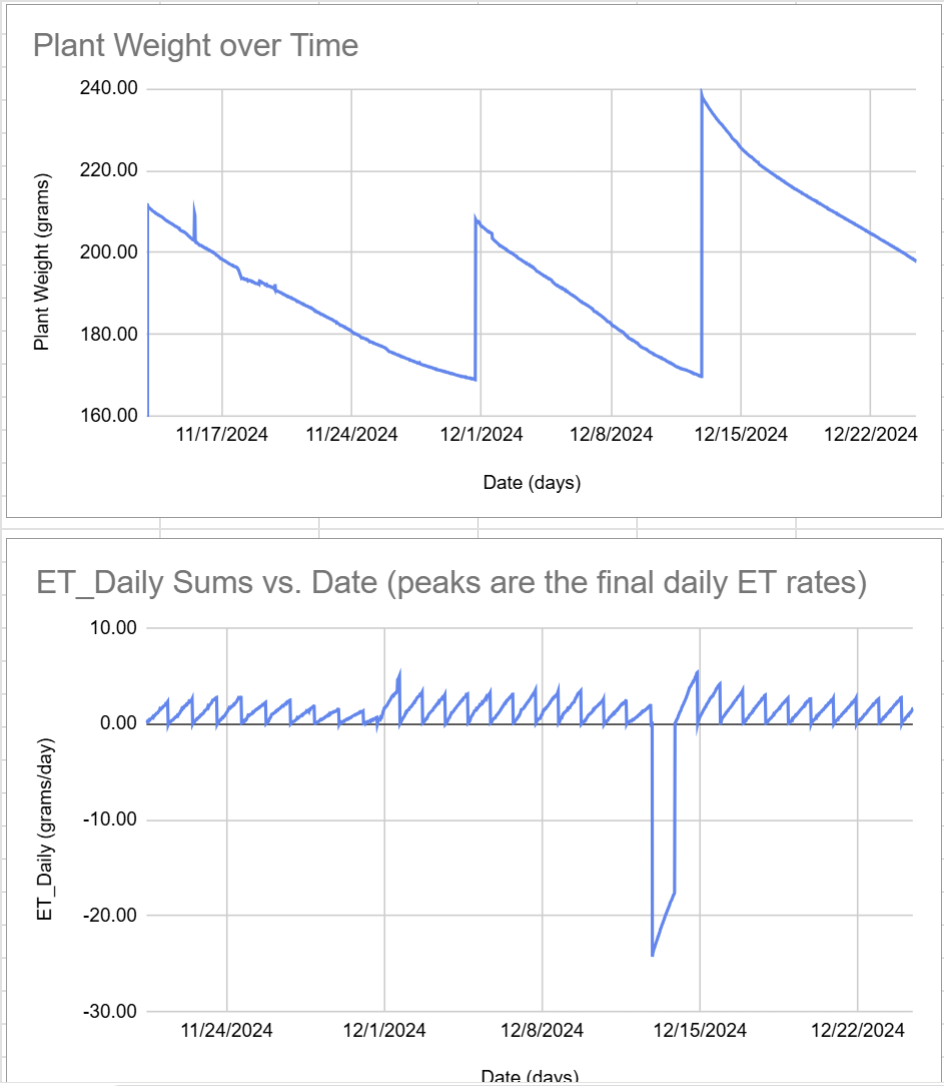

By looking at the slope of the weight of the plant, you can calculate evapotranspiration (ET)- the rate at which a plant is intaking water for homeostasis. When the ET rate decreases, it is time to water the plant.

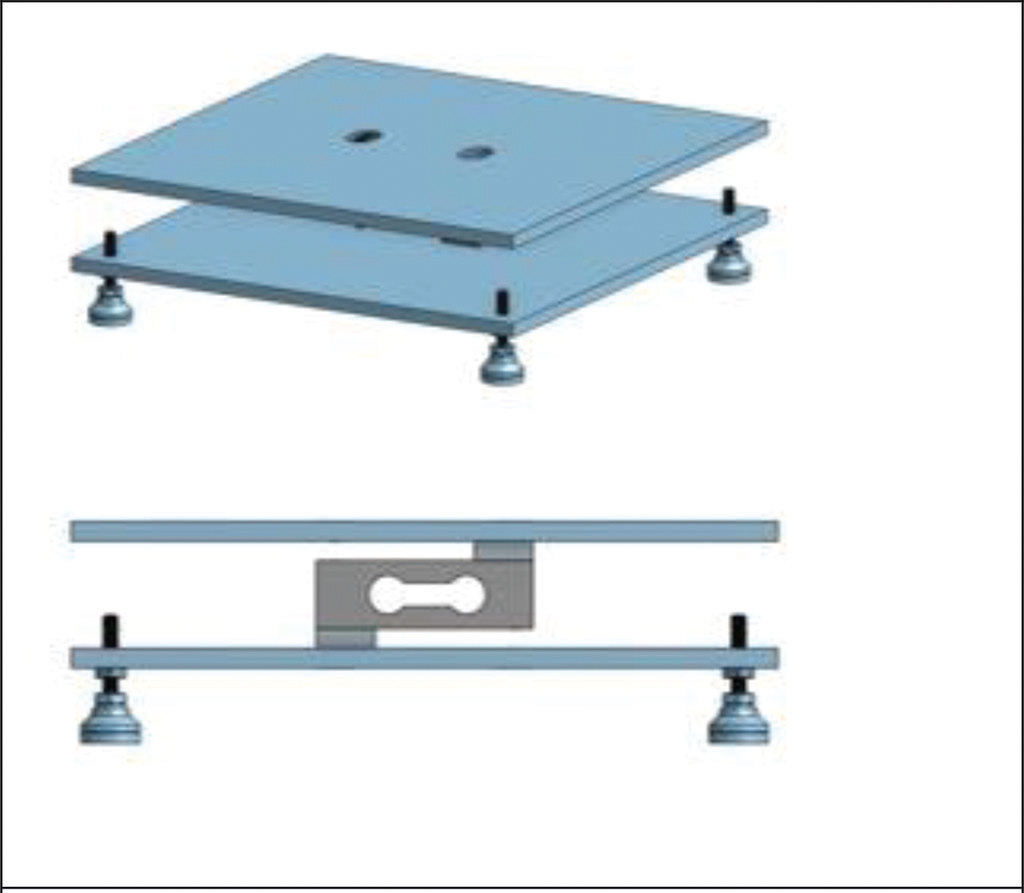

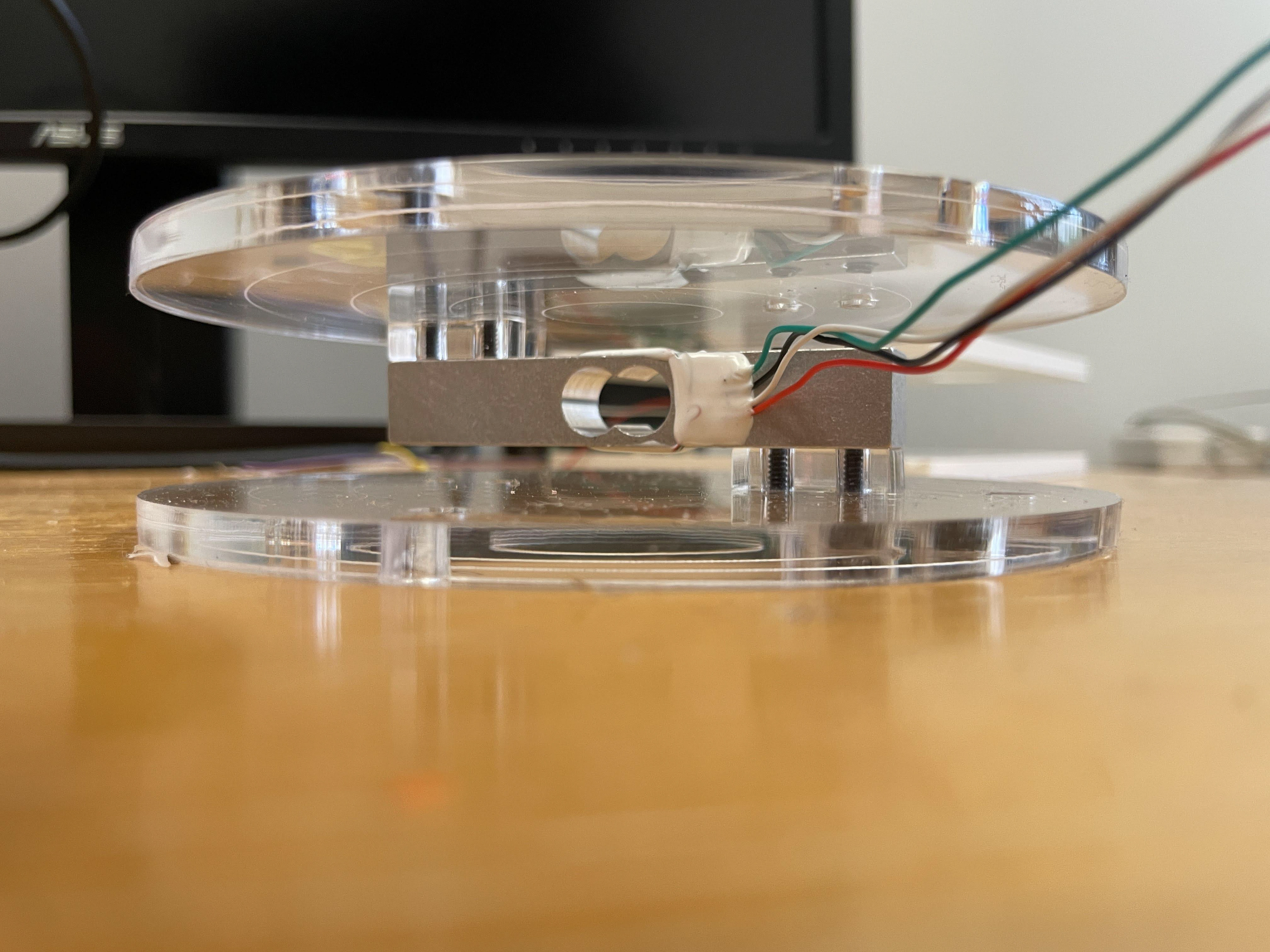

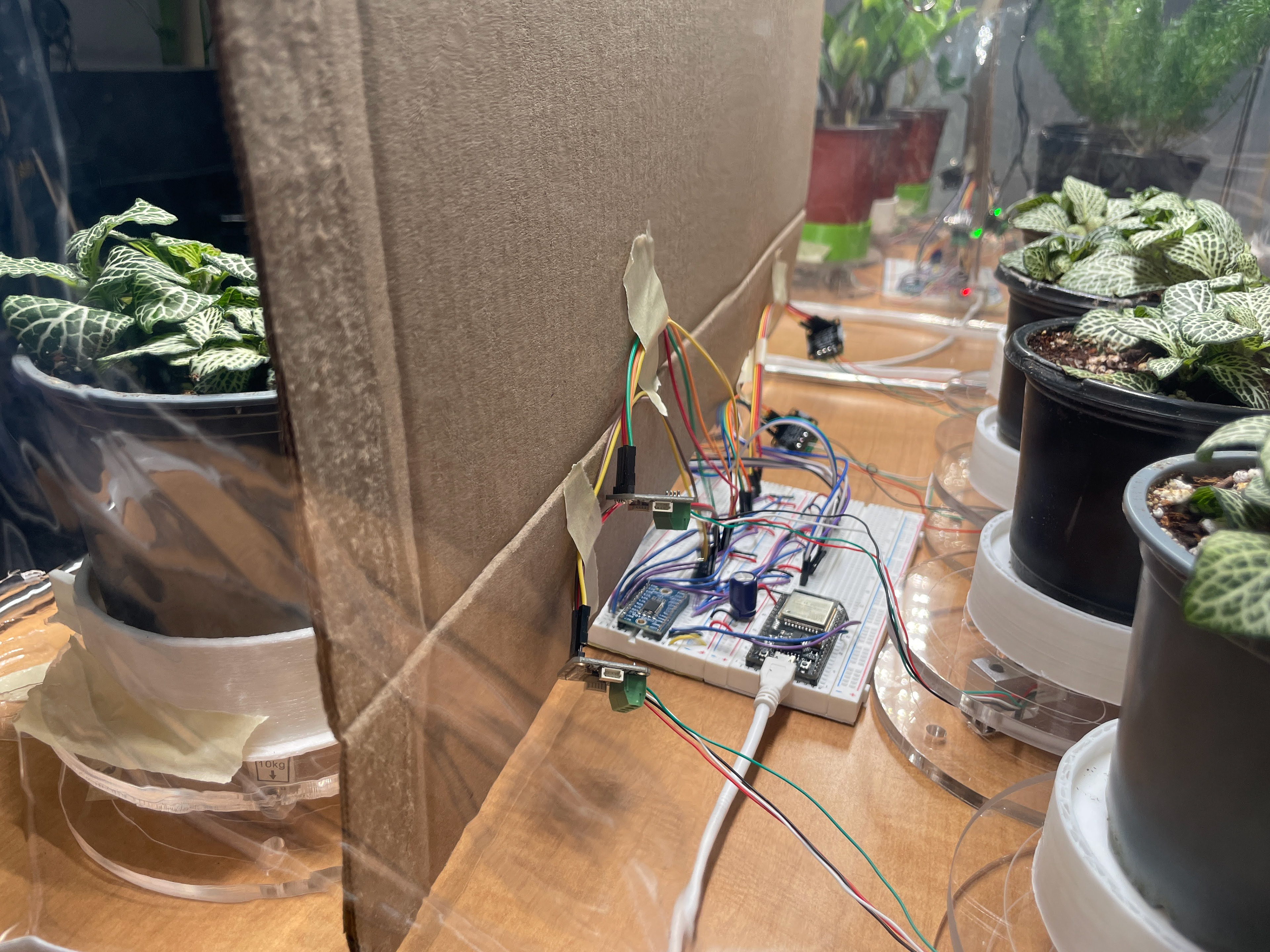

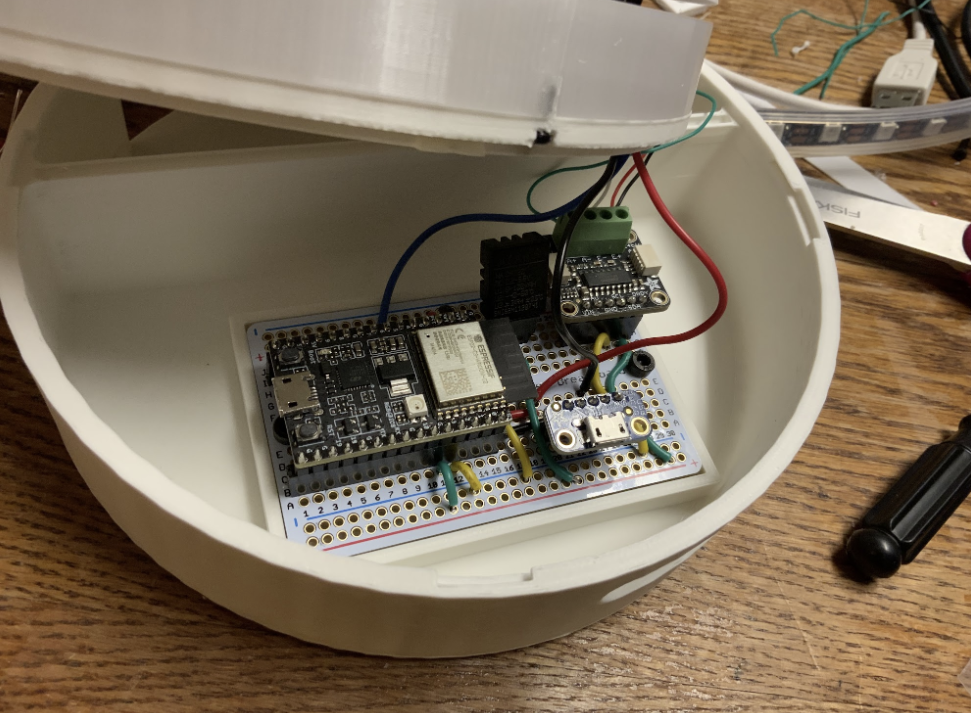

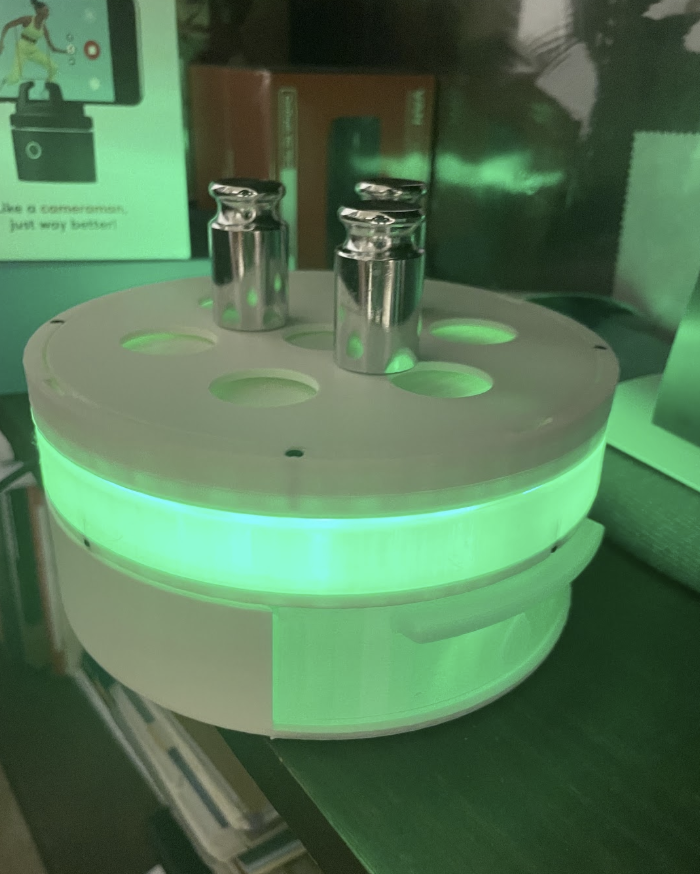

Using laser-cut acrylic parts, 3D-printed parts, load cells, and analog-to-digital converters, we created our own lysimeters and another test setup to grow plants using this method.

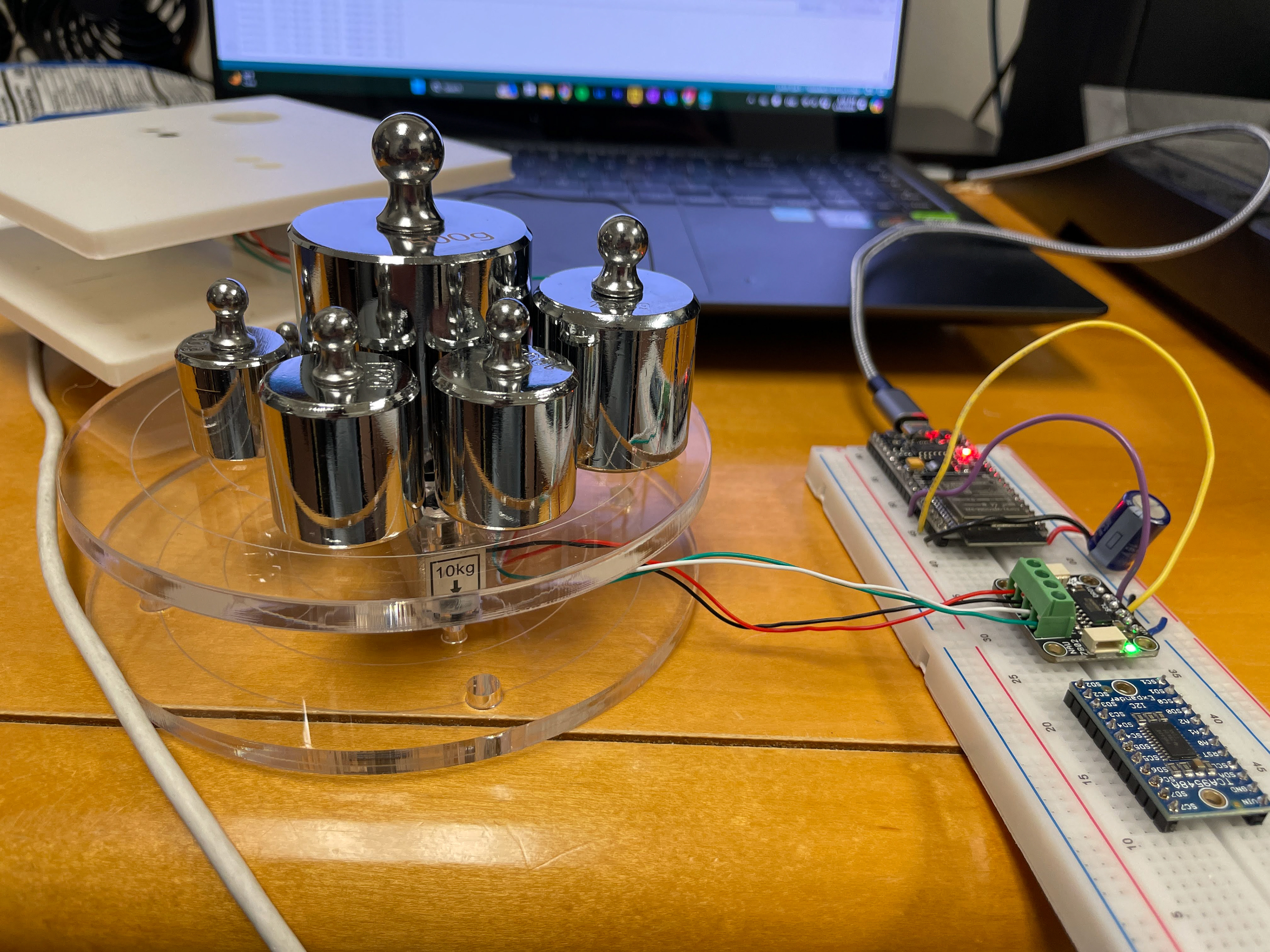

I wired and coded the electronics to send data through the ESP32s through Google Sheets. I also ran calibration and accuracy tests using standard weights.

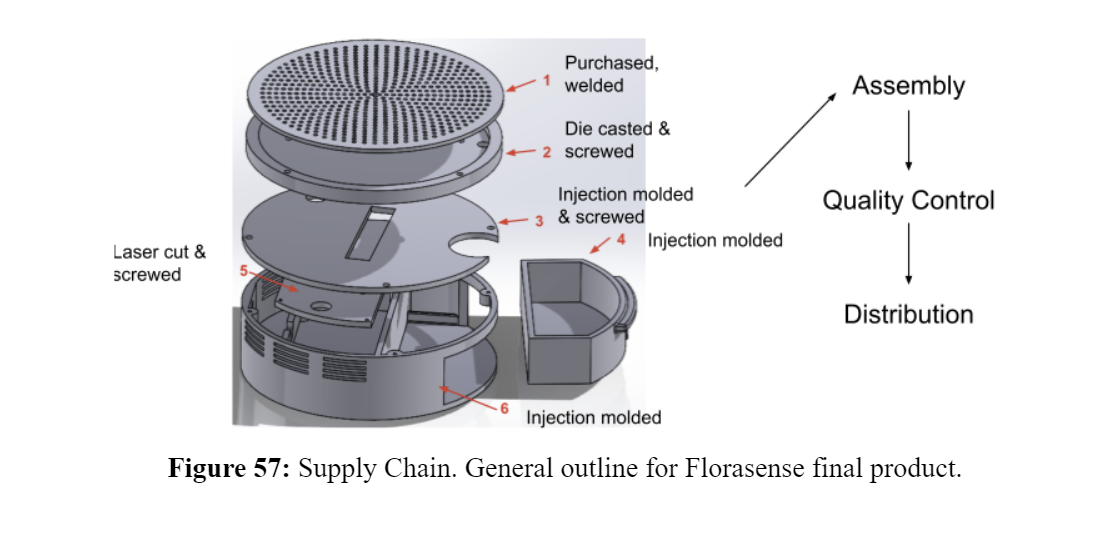

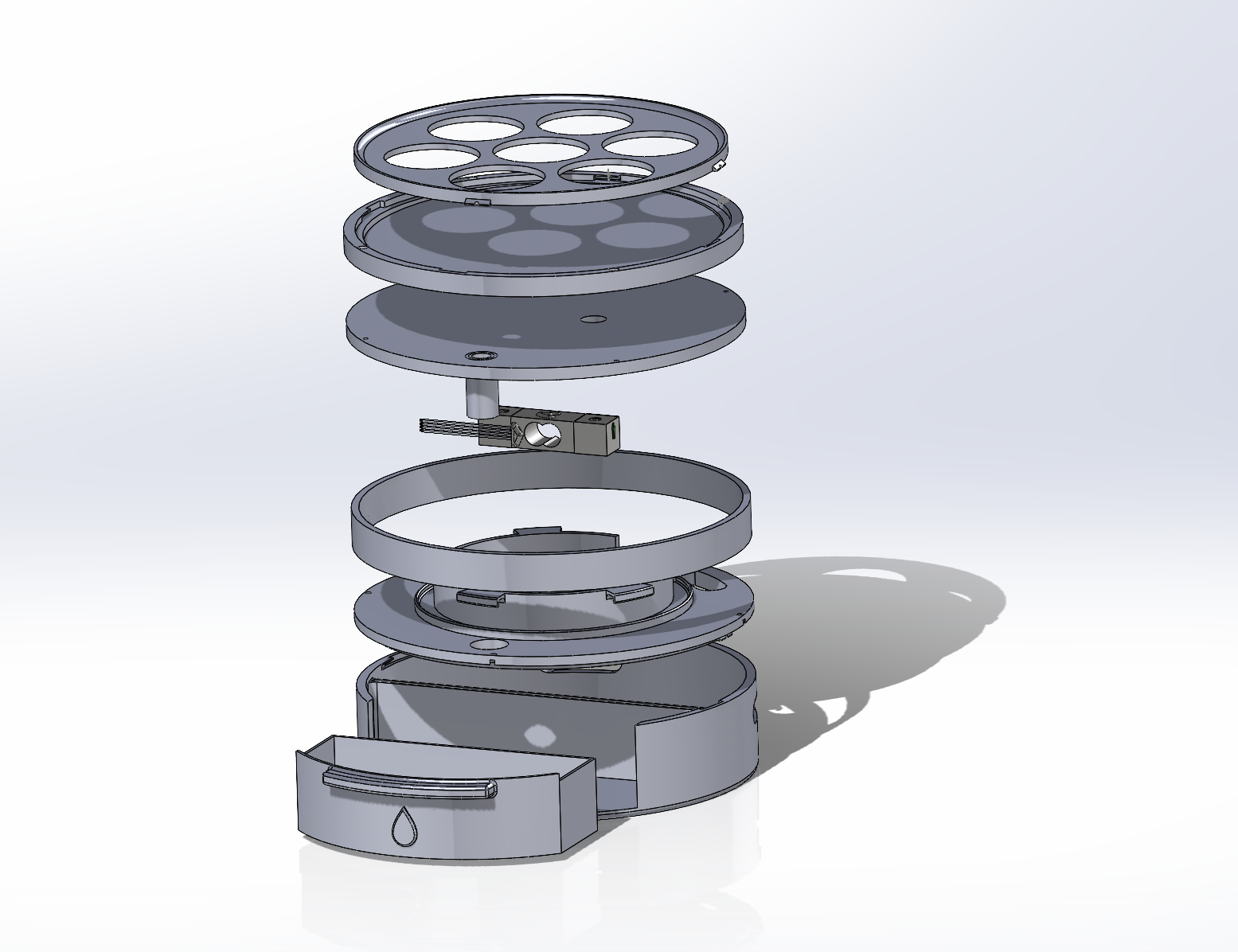

We went with this lysimeter technology to create our final prototype: Florasense. The load cell inside measures the weight of the plant and turns the LED red when the evapotranspiration rate is too low. We designed the parts with the manufacturing processes and lean design in mind.

Our capstone class is now over but that doesn't mean we're done yet. Our team wants to take Florasense to the market, but several next steps remain.

The research is not conclusive on which evapotranspiration level requires watering the plant. We found a paper using 40% of the highest evapotranspiration rate but did not have sufficient time to test this. Further testing needs to be done.

I was able to grow an orchid plant for a month and a half using a prototype lysimeter that signaled for watering when the daily evapotranspiration rate decreased to under 50% of the peak evapotranspiration rate. This testing will be done on a variety of different plants.

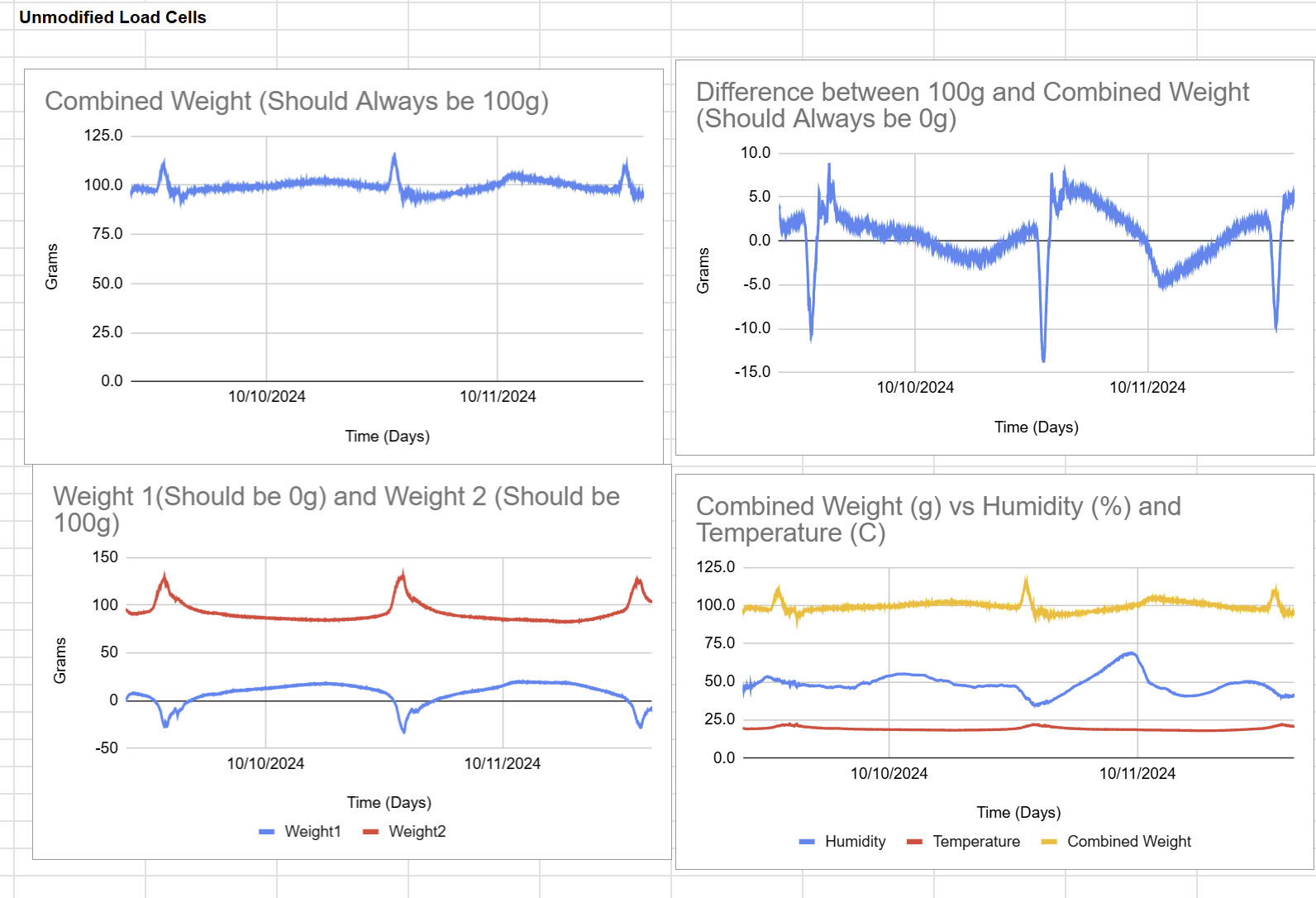

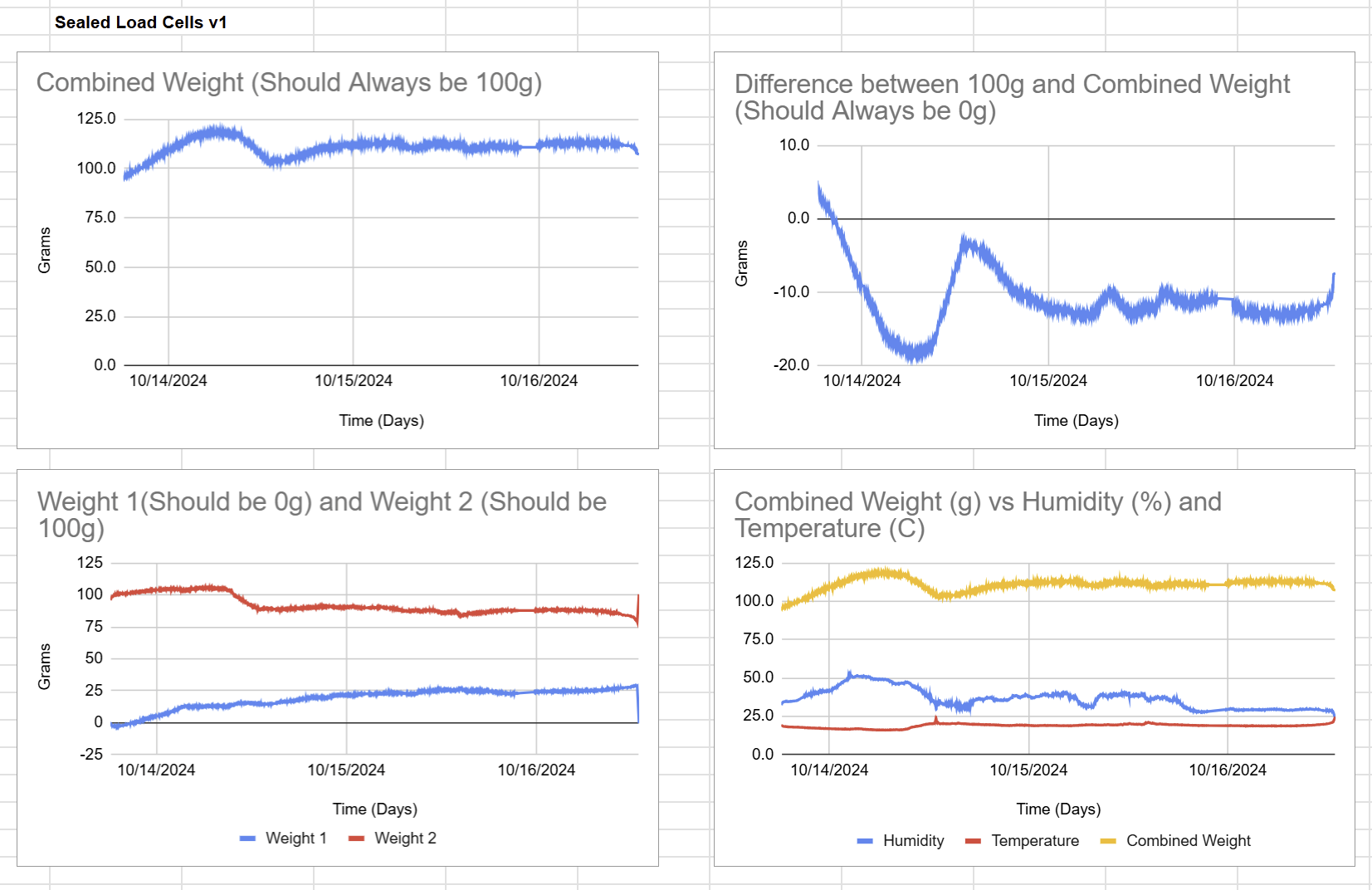

Load cells are known to drift due to temperature but our regression had too low of an R^2 score to be reliable. We believed that humidity was affecting the readings from the load cells. I was able to verify through tests and a research paper utilizing our load cells that no regression could be reliable enough to salvage the readings from our Adafruit load cells.

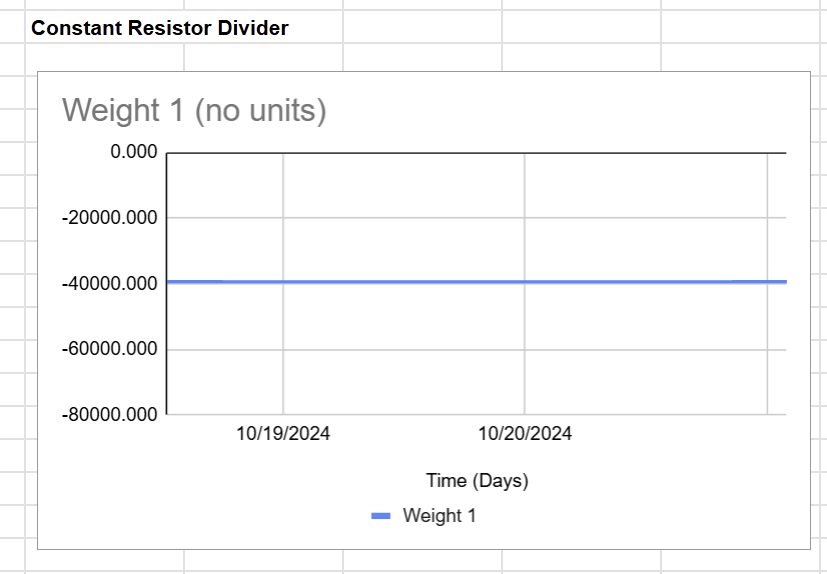

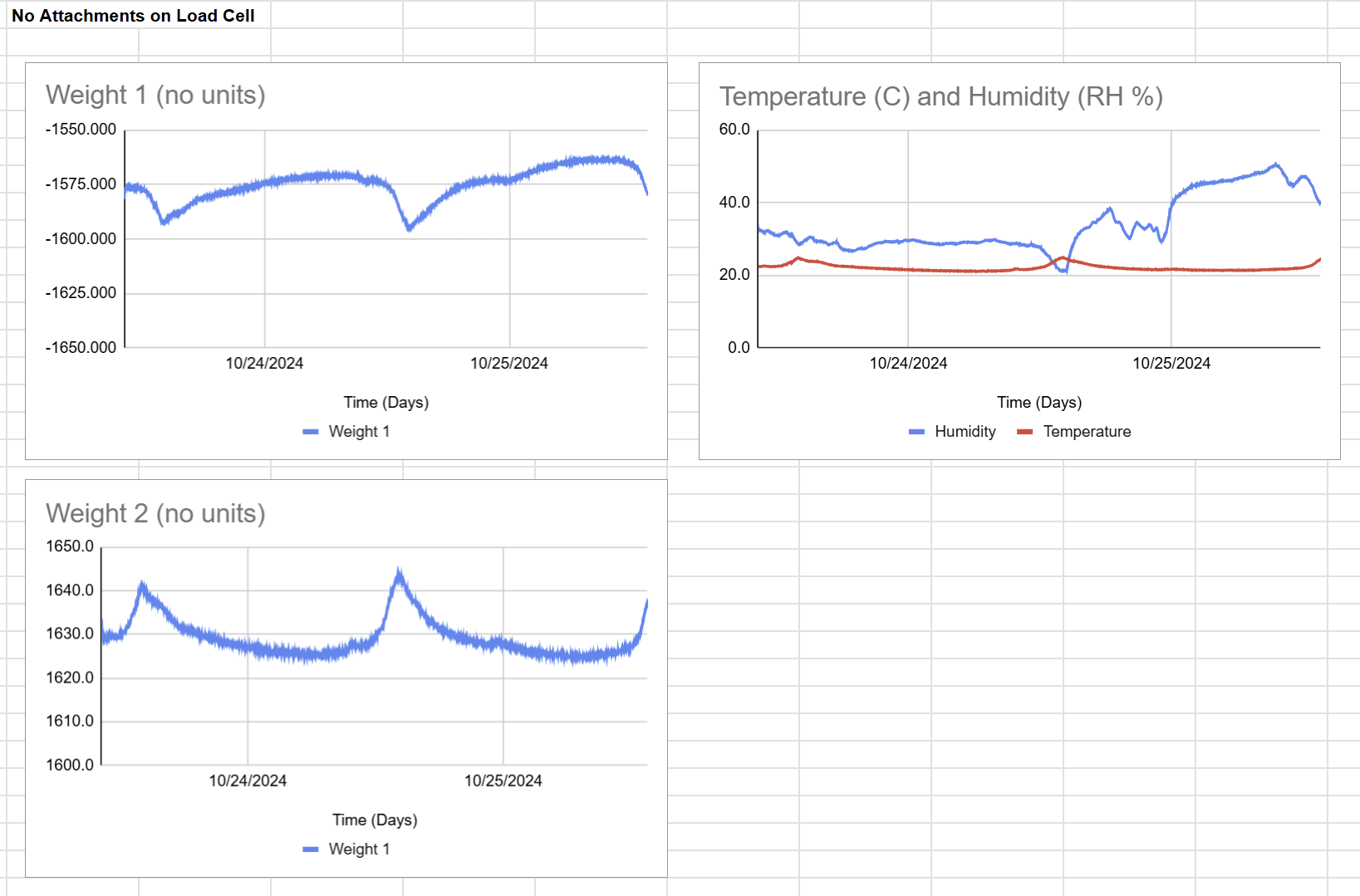

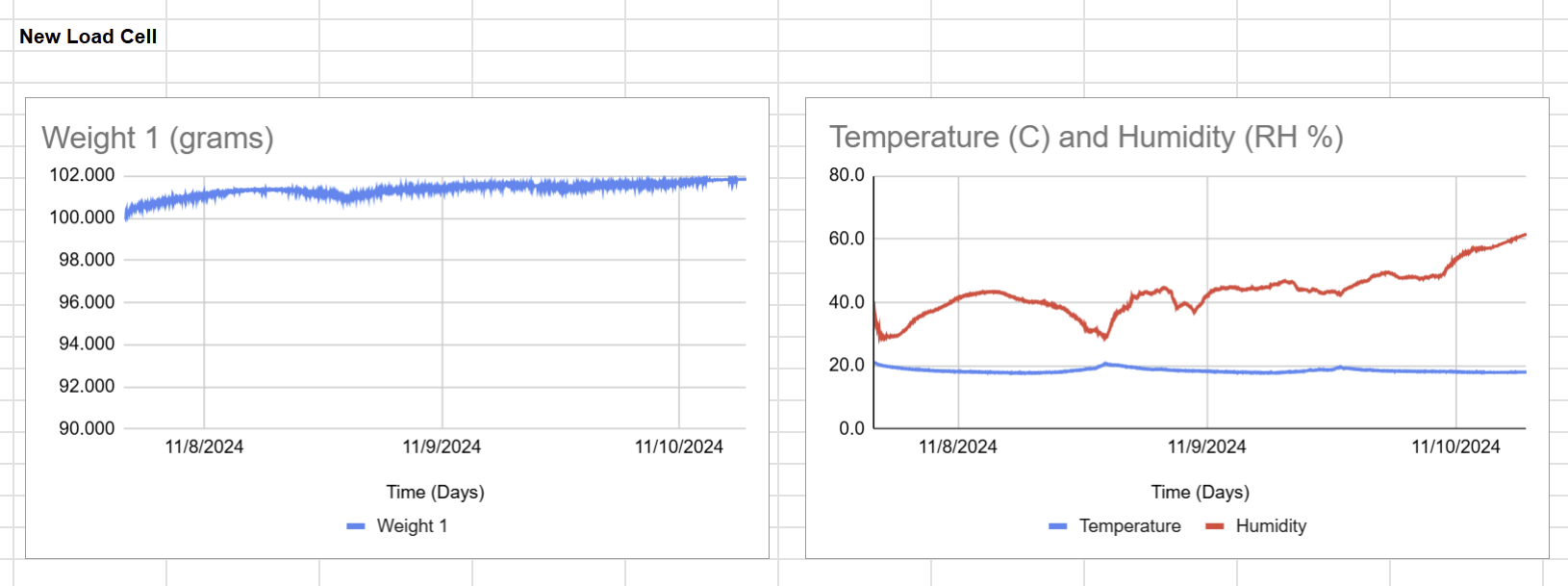

First, I tried to sum the readings from a loaded load cell and an empty load cell to get a constant reading, but the readings fluctuated by tens of grams. I then tried to seal the load cell with a waterproof sealant, remove all attachments on the load cell, and shield the load cells from sunlight, but was still unable to get a constant reading. I then created a resistor divider to see if the analog-to-digital converter would read a constant value and the reading was extremely constant over several days. This signaled that the load cell was the issue, and once I purchased a different load cell, the readings fluctuated by only several grams. Thus, I was able to solve the load cell performance issue.

Our final prototype had positive feedback in user interviews but we were not able to do long-term testing with users. We will conduct long-term plant-growing trials with new plant owners before taking Florasense to market.

Post-graduation, I have been further refining the design of the prototype, simplifying the electronics to minimize cost, and conducting user testing and research to prove our product. I aim to take this to market and manufacture the product domestically.

Thank you, Team 4 teammates!

Quarter 3 Final Report